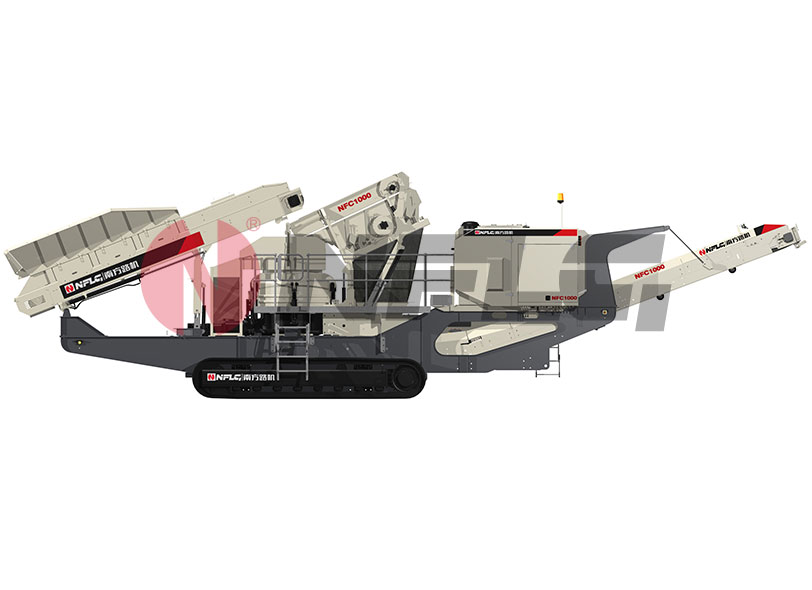

Brief introduction: Tracked mobile cone crushing station has featured an excellent performance, efficient productivity and stable capacity on aggregate producing and mine topsoil. Hydraulic driven cone crushing host with adjusted speed and high yield can guarantee the finished product grain shape. Pre- screening system is an option which can remove the fine materials before it enters into the host to reduce the wear of the host. Receiving hopper and belt feeder has the metal detection system and unloading system which can play a protective role when the metal objects enters into the host and impurity discharging system can directly remove the metal material out of the machine and reduce the loss. Besides, the plant features quick installation, easy maintenance, and high ratio of crushing, high productivity and advanced electric control system.

| Application | Secondary and tertiary crushing and aggregate producing |

| Capacity | 260tph Material is based on limestone with bulk density 1.6t/m³ Practical capacity depends on raw material feeding size,mesh size and material conditions. |

| Hopper capacity | 5m3(8m3) |

| Chamber | ATUOMAX HC1000 Standard(optional chamber: super rough, rough, standard, sand-making) |

| Discharge setting range | 19~36mm(Standard type) |

| Maximum feeding size | 160mm(Standard type) |

| Power | Tier3/EU Stage 3A: CAT C9 ACERT 261kw(350HP) |

| Conveying weight | 36t(38t equipped with pre-screen system) |

| Transportation size | 16.9m(length)X2.8m(width)X3.5m(height) |

Copyright Notice 2002-2026 global-ce.com Construction Machinery Online. All rights reserved.

Address: Room 901, Building C, Ruipu Mansion, Hongjunying South Road No.15, Chaoyang District, Beijing.100107 P.R.China